In today’s technological landscape, the demand for hermetic feedthroughs that provide both electrical and pressure integrity is higher than ever before. These critical components are used in various industries, including aerospace, automotive, medical, and telecommunications, to ensure the reliable performance of electronic systems in harsh environments. Testing these feedthroughs for their ability to maintain electrical and pressure integrity is crucial to guaranteeing their efficiency and longevity.

What are Hermetic Feedthroughs?

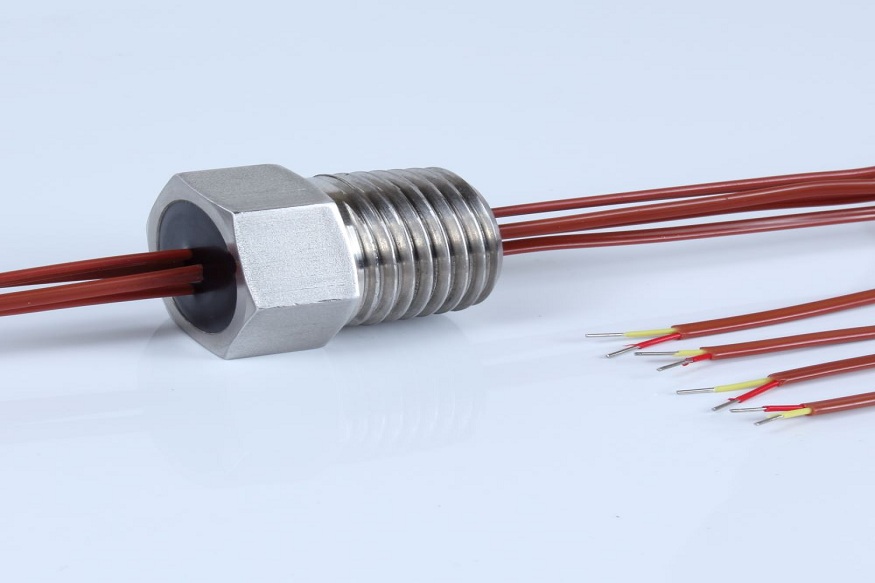

Hermetic feedthroughs are specialized connectors that are designed to pass electrical signals or power through a sealed barrier, such as a vacuum or pressurized environment. They are commonly used in applications where regular connectors would allow moisture, dust, or other contaminants to compromise the system’s performance. By creating a hermetic seal, these feedthroughs ensure the protection and reliability of electronic components in challenging conditions.

Importance of Electrical Integrity Testing

Testing hermetic feedthrough for electrical integrity is essential to verify that they can effectively pass electrical signals without any leakage or interruption. This testing involves subjecting the feedthroughs to various electrical conditions, such as voltage and current levels, to ensure that they can maintain a consistent flow of electricity. Any inconsistency or breakdown in electrical conductivity can lead to malfunctions or failures in the electronic system, highlighting the significance of thorough testing in this aspect.

The Role of Pressure Integrity Testing

In addition to electrical integrity, pressure integrity testing is equally important in evaluating the performance of hermetic feedthroughs. These feedthroughs are often used in environments with high pressure differentials, such as aerospace or deep-sea applications, where any leakage could result in catastrophic consequences. Pressure integrity testing ensures that the feedthroughs can withstand the specified pressure levels without any compromise to the seal, thus maintaining the system’s overall integrity.

Common Testing Methods

There are several common methods used to test hermetic feedthroughs for both electrical and pressure integrity. One such method is the helium leak test, where the feedthrough is pressurized with helium gas, and any leaks are detected using a mass spectrometer. This highly sensitive test can identify even the smallest leaks in the hermetic seal, ensuring the feedthrough’s reliability under extreme conditions. Another method is electrical continuity testing, which verifies the feedthrough’s ability to maintain a consistent flow of electricity without any interruptions.

Conclusion

In conclusion, testing hermetic feedthroughs for electrical and pressure integrity is a critical step in ensuring the reliability and performance of electronic systems in challenging environments. By subjecting these components to rigorous testing methods, manufacturers can guarantee that their products meet the highest standards of quality and safety. As technology continues to advance, the demand for reliable hermetic feedthroughs will only increase, making comprehensive testing an indispensable part of the production process.

Leave a Reply

You must be logged in to post a comment.