From scorching deserts to freezing tundra, some places on Earth truly push materials to their limits. But thanks to continued innovation, we can create super-tough materials that can survive crazy conditions.

Shrugging Off Intense Heat

Imagine something that could withstand the heat of a rocket launch or the blazing temperatures inside an industrial furnace. That’s where advanced ceramics and special composite materials come into play.

One example is hafnium carbide – a super-hard refractory ceramic capable of remaining stable at temperatures over 4,000°C. Composites that blend ceramics with metals or carbon fibers can also handle extreme heat while providing strength and toughness. These high-temp champions get their incredible resistance from their highly covalent atomic bonds and crystal structures.

Laughing at Arctic Chills

On the other end of the temperature spectrum, cryogenic materials are fantastic at taking on brutal cold. Stuff like austenitic stainless steels can maintain their strength and flexibility even when approaching absolute zero (-273°C). They are used in applications like liquid gas storage, space exploration, and some crazy cryogenic experiments.

The key is controlled thermal contractions and energy-absorbing crystal structures that prevent brittle fracturing. Some polymers like PCTFE (Polychlorotrifluoroethylene) also remain flexible at ultra-low temperatures, making them ideal for tasks like Arctic drilling and exploration.

Surviving Crushing Force

From deep underground to the ocean depths, immense pressure can squeeze and deform regular materials. But not ultra-high-molecular-weight polyethylene (UHMWPE). This specialized plastic has incredible impact resistance and anti-abrasive properties, able to withstand tremendous forces without shattering or deforming.

UHMWPE gets its super toughness from its tightly interlocked molecular chains and semi-crystalline structure. It’s used for things like body armor inserts and industrial equipment built to take major impacts.

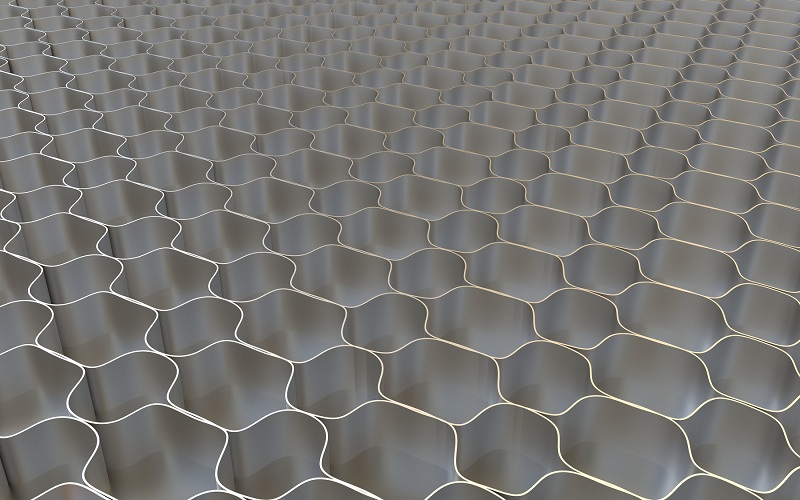

Honeycomb Secrets

You know that ultra-light but mega-strong structure found in beehives? Materials like Nomex honeycomb mimic that design to create extremely sturdy yet lightweight components. According to the folk at Axiom Materials, this geometry maximizes strength while using minimal material. Brilliant for applications where heavy armor is needed but weight is an issue.

From emergency response gear to aerospace engineering, honeycomb materials provide impressive protection at a fraction of the weight of solid materials. It’s all about optimizing the strength-to-weight ratio through clever geometric design.

Molecular Marvels

Through advanced chemical and nano engineering, we can tweak materials at the molecular level for truly customized super-durability. Liquid crystal polymers and ultra-high-molecular-weight polyethylene can have incredibly aligned molecular chains, making them extremely tough and resistant to chemicals or radiation.

Controlling things like molecular orientation, crystallinity, and polymer chain makeup means scientists can basically build a “molecular armor” to spec for whatever harsh conditions they need to overcome.

Designing for the Depths

From underground mines to deep sea exploration, intense hydrostatic pressure is a major challenge. To survive the crushing might of water depths, materials like maraging steel and glass-reinforced plastic are employed. Their unique compositions and molecular structures prevent deformation, even under immense undersea pressures.

Crazy stuff like deep-water oil rigs and submarine vessels wouldn’t be possible without these ultra-tough, pressure-defying materials. With their incredibly high tensile strengths, they simply don’t buckle under the force of thousands of pounds of ocean bearing down.

Conclusion

While today’s durable materials can handle crazy heat, cold and impact, scientists are always striving to create tougher, lighter and more versatile options. Futuristic nanomaterials like graphene and carbon nanotubes show incredible promise. With their ultra-high strength-to-weight ratios, they may usher in a new generation of materials for even more extreme environments like space exploration.

From the scorching surfaces of Venus to the vacuum of deep space, there’s no limit to where advanced materials could take us as we keep innovating and exploring. Who knows what mind-bending materials breakthroughs await around the next corner?

Leave a Reply

You must be logged in to post a comment.